Ready to reboot?

E-commerce is booming, so instant fulfillment automation should be booming, too. But even the most advanced robotic solutions serving e-commerce today were developed before the e-commerce era, and they are struggling to adapt to the amazing speed sought by e-shoppers.

download brochure

Product

download brochure

What is instant

right-size packaging?

Instant right-size packaging allows the fulfiller to create

- right-size boxes

- on-site

- instantly

according to the provided dimensional data.

BOXOLOGIC Robotic Instant Right-Size Packaging

Boxologic Robot

from corrugated fiberboard

to instantly created

right-size box on -site.

BOXOLOGIC Features

Instant Right-Size Case Building

Builds right-size cases instantly.

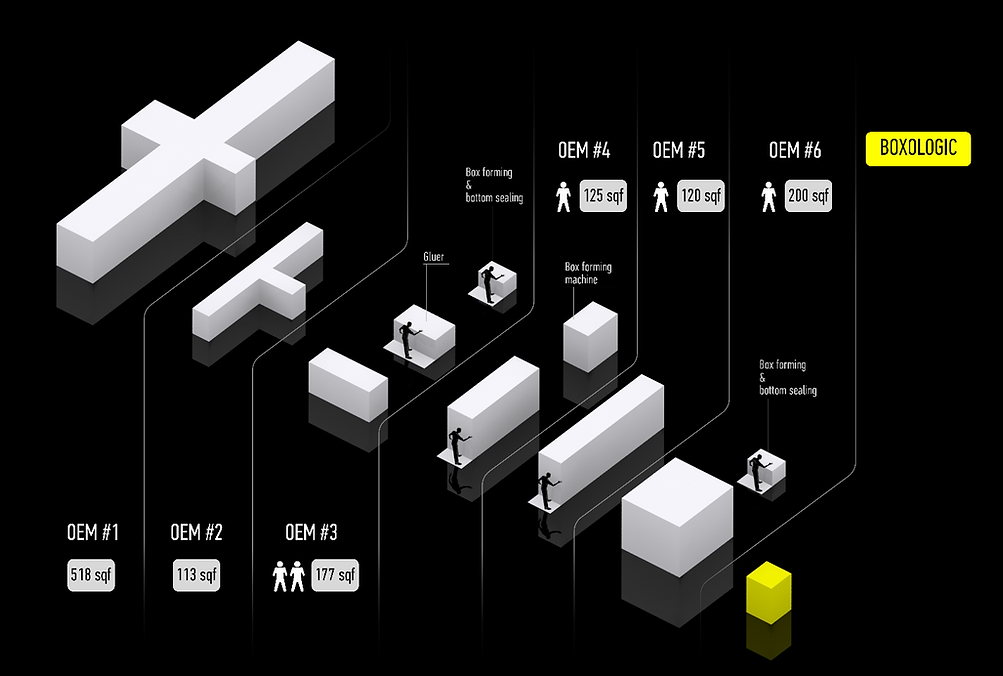

Ultra-Small Footprint

The smallest footprint in the world. Industry average is 200sqf.

Hands-free process from Flat to Sealed Full Case

Creasing, line scoring, case forming, bottom sealing, and top sealing—all-in-one with “0” human intervention.

Only 1 SKU of Corrugated Fiberboard (CF)

Our revolutionary engineering solution uses only one SKU of Corrugated Fiberboard to produce any size of box required.

Lowest waste-rate in the industry

It creates the least corrugated waste—only 1/5 as much waste as the industry leader, and 1/10 as much waste as the industry average.

Competition

Comparison Base

Number of operator

From flat Corrugated Fiberboard (CF)

to top- and bottom-sealed, filled case

BOXOLOGIC is the only solution on the market for building, creasing, line scoring, case forming, bottom sealing, and top sealing—all-in-one with “0” human intervention, and all within the smallest footprint available.